INDUSTRY SECTORS WE SERVE

IN NEED OF A HEATING SOLUTION?

- Heating + control, offering complete solutions

- Backer HTI

- / Products

- / Heating

CUSTOMIZED HEATING SOLUTIONS

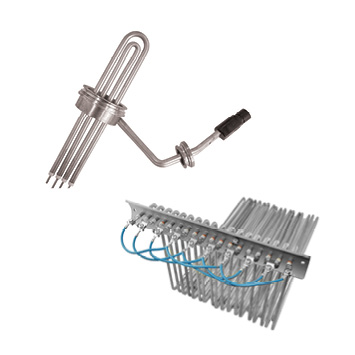

Backer HTI is the expert when it comes to any kind of heating solution - whether you are heating liquids, air, a metal or any other material. We are skilled in a wide selection of technologies guaranteeing our customers an optimal solution for their specific heating element needs.

If you're looking for quick deliveries, low cost production, custom solutions, or industry /application specific collaboration Backer will help find a heating solution that works best for you.

HOW ABOUT INTELLIGENT HEATING?

In addition to basic heating elements we also have intelligent heating.

If you add one of our control and measurement solutions to your heating device, it will not only ensure that no unnecessary heat is lost, but you will also reduce operating costs as well as joining us in contributing to a more sustainable future.

OUR PRODUCTS

SUPPORT AND TOOLS

BACKER HEATING TECHNOLGIES · 1390 Gateway drive · ELGIN · TEL: 1-847-931-1304

Copyright © 2023 Backer HTI