INDUSTRY SECTORS WE SERVE

TUBULAR HEATING

- uniform heat source over a distributed area

- Backer HTI

- / Products

- / Heating

- / Tubular heating

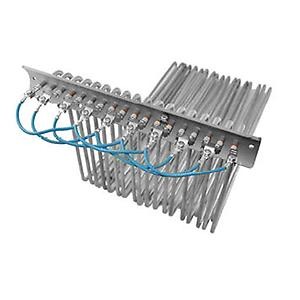

TUBULAR HEATING ELEMENTS

Tubular heating elements can be used for many applications which require a uniform heat source over a distributed area. Tubular heaters are very versatile and can be designed with wide range of diameters, lengths, sheath materials and voltage ratings.

The flexibility of these heating elements allows them to be formed into virtually any shape, including precision forming for a tight fit into milled grooves of manifold surfaces. Multiple termination options are available depending on application requirements.

SOLUTIONS

HEATING TECHNOLOGIES

AIR HEATERS

Air heaters is a group of heating elements that is designed to the highest standard by first understanding the air mixture to be heated.

We design air heating solutions by following strict guidelines to ensure the safest, most efficient heating solution possible.

IMMERSION HEATERS

Immersion heaters is a group of heating elements that is the common alternative for direct heating of various liquids such as water, oil, solutions, industrial baths etc.

DEFROST HEATERS

This group of tubular straight elements can be supplied in a range of materials dependent upon use and are supplied fully annealed for bending.

Our straight-length defrost heaters are typically employed to defrost coils and evaporating pans.

SUPPORT AND TOOLS

BACKER HEATING TECHNOLGIES · 1390 Gateway drive · ELGIN · TEL: 1-847-931-1304

Copyright © 2023 Backer HTI