INDUSTRY SECTORS WE SERVE

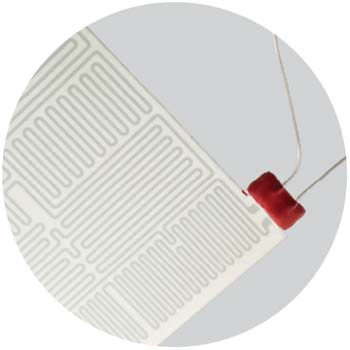

FLEXIBLE FOIL HEATING

- Thin, multiple circuits & even temperatures

- Backer HTI

- / Products

- / Heating

- / Flexible foil heating

FLEXIBLE FOIL HEATING

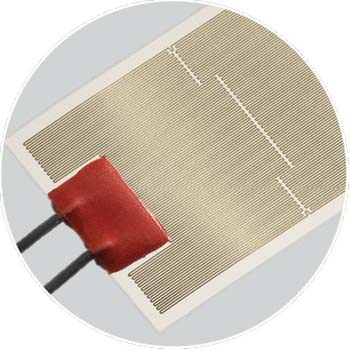

Flexible foil heaters provide precise, dependable and immediate heat transfer for many applications.

Our innovation center is employed with highly qualified engineers continuously working with new applications and materials. This allows us to find the optimal heating solution to meet your needs and produce it quickly.

Our flexible heaters consist of an etched-foil laminated between one of our flexible insulations. Our flexible foil heaters also offer many more benefits including custom watt densities, various dielectric strengths, thin or thick profiles, added pressure sensitive adhesives (PSA) or bond directly to heat sinks.

SOLUTIONS

HEATING TECHNOLOGIES

Backer HTI uses a wide selection of circuit and insulation materials and work together with our customers to find a solution that best fits their needs.

Foil heating is an excellent solution when good thermal transfer is needed in a specific area, and are used in thermal control design to protect components under cold-case environments, or to make up for heat that is not dissipated.

At Backer's innovation center, highly qualified and experienced engineers continuously experiment with new materials to continue improving our processes.

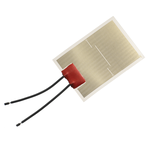

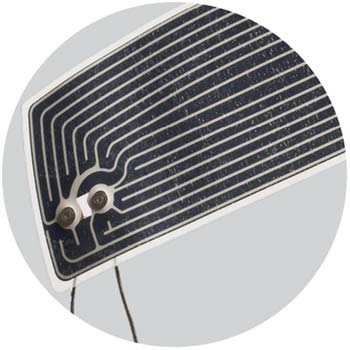

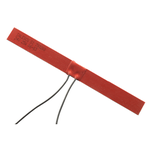

POLYESTER HEATERS

Superior heat transfer and uniform heat output. Fast warm up with long life cycle.

Max. power density: 0,6W/cm²

Max. temperature: +105°C

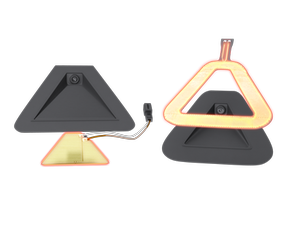

Mirror heaters · De-icing equipment · Hand grip heaters · Rear view mirrors · Battery heaters

Product examples

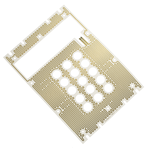

Heater for snowmobile handlebars

Heater for keyboards

Heater for shoes/feet

Product examples

Heater for headlights

Heater for rear view mirrors

Heater for coffee makers

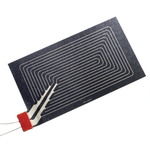

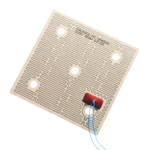

PRINTED POLYMER HEATERS

Low power, constant wattage with a large span of resistivity. Insensitive to small damages.

Max. power density: 0,1W/cm²

Max. temperature: +70°C

High voltage, small area applications · Waterbed heaters · IR targets · Floor heating

Product examples

Floor heating

Waterbed heaters

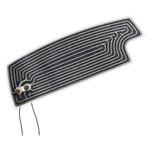

POLYIMIDE HEATERS

Thin and semi-transparent with excellent dielectric strength. Resistant to chemicals.

Max. power density: 1,3W/cm²

Max. temperature: +200°C

Military and aerospace · Medical diagnostic instrument · LCD displays · Lens heaters · Laboratory research

Product examples

Heaters for alco locks

Heater for camera/lens

Heater for anesthesia

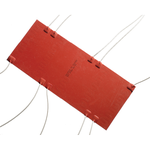

SILICONE HEATERS

Excellent temperature properties. Can be vulcanized to metal parts.

Max. power density: 1,3W/cm²

Max. temperature: +230°C

Food service equipment · Medical respirators · Ultrasonic cleaners · Freeze protection and condensation prevention

Product examples

Heater for railway couplers

Heater for industrial application

Heater for ultrasonic wash

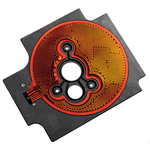

MICA HEATERS

High power density. Fast warm up and high working temperatures.

Max. power density: 5W/cm²

Max. temperature: +600°C

Food service appliances · Semiconductor industry · DNA analyse · Radiators/heating panels · Packing/strapping/sealing equipment

Product examples

Heater for packaging machine

Heater for medical application

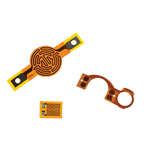

PEN HEATERS

PEN is similar to PET but has higher chemical, thermal, mechanical and electrical properties.More cost effective compared to polyimide.

Max. power density: 1W/cm²

Max. temperature: +160°C

Electronic devices · Radiators · DNA Analysis · High power standard elements

Product examples

Heater for DNA analysis

Heater for radiators

FRTP HEATERS

(Fibre Reinforced Thermo plastic) Stiff, extremely durable, water resistant.

Max. power density: 0,1W/cm²

Max. temperature: +100°C

Radiator panels · Heaters for rough conditions

PVC HEATERS

Very flexible, water proof and acid resistant with high mechanical strength.

Max. power density: 0,1W/cm²

Max. temperature: +70°C

Waterbed heaters · Water heaters · Military equipment · Slim blankets / Surgery beds

Product examples

Heater for surgery beds

SUPPORT AND TOOLS

BACKER HEATING TECHNOLGIES · 1390 Gateway drive · ELGIN · TEL: 1-847-931-1304

Copyright © 2023 Backer HTI

%20(2)%20FlexkortFrilagd1.png)